The role of heavy engineering in power sector

Electricity has become an integral part of our society. Every single function that was once done through manual labor, is now done by machines using electricity. Candles switched to light bulbs, plows to tractors, hand powered grinder, blenders, drills to electric powered counterparts.

Appliances and electronics are an integral part of infrastructure. Megastructures, like power plants, turbines, generators and transformers are needed to power entire cities. Power is generated and reaches its target in 3 major steps:

- Generation of electricity: Raw fuels or flowing fluids hit the blades of a turbine, which converts mechanical (kinetic) energy into electrical energy with the help of generators.

- Transmission of electricity: From turbines the mechanical energy changes into electrical energy and generators transmit the electricity to distribution centers.

- Distribution of electricity: Transformers, towers and electric poles are used to distribute the power in the city.

Below are the integral equipment manufactured by heavy engineering for the power sector:

- Steam Generators

- Turbines

- Vessels and heat exchangers

- Transformers

Steam Generators

Steam generators use heat to convert water into steam. These generators are used in all the steam turbine power plants- like Nuclear reactors and coal-fired plants.

In nuclear reactors, the core, where reactions take place, has a shape of a dome and running water passes around the dome. The reaction happening in the reactor is an exothermic reaction, which changes water into steam and moves out while fresh water comes in. That steam is used to move the turbine blades.

In coal-fired power plants, the process is quite similar to boiling water on a stove. Instead of vessels there are many heat resistant pipes going through the furnaces. Fresh water is running in all of them, as soon as water passes through an extremely hot furnace it changes into steam. Which further turns the turbine.

Steam generators vary in shapes and sizes. Various high-performance alloys and super alloys are used to make pipes and structures. As the core of power plants changes the generator’s materials, shapes, and systems change as well.

Turbines

Fan-like blades are attached to an induction motor, which rotates when hit by the power source, like water, wind, or steam. The kinetic energy of the fluid is converted into electrical energy.

The size of turbines in dams, windmills, and power plants are around 50 m to 250 m in diameter. That’s how these turbines produce electricity for a town or even a city.

Turbines differ in matter of the materials and shape, although the mechanism and purpose is same everywhere.

- Steam Turbines: These turbines cover the majority of power plants. Steam turbines, as the term defines, uses steam to generate electricity. This steam is produced by boiling water with various fuels- like in coal power plants, solar power plants, and nuclear power plants. The material used to make these types of turbines have higher resistance to heat and rust, to avoid expansion or rusting. Generally low-alloy steel is used to make the rotors.

- Wind Turbines: These turbines are generally used in windmills. They are lighter and have a much bigger diameter than steam turbines. They use the flow of wind to generate electricity. Generally Steel is used for larger mills and aluminum for smaller ones, to make them lighter.

- Gas turbines: Gas turbines use compressed air mixed with a fuel to generate hot gas. Which in turn moves the turbine to generate electricity. Best example for gas turbines would be diesel generators. But gas turbines have various types and sizes. Generally used materials are steel, aluminum alloys, magnesium alloys, titanium alloys, superalloys of iron, nickel and cobalt bases.

- Water turbines: Water turbines are used in dams, and other hydro power plants. They come in multiple sizes, and are smaller than wind turbines. Generally fiberglass, carbon fiber or reinforced plastics are used to make the rotor blades. As these turbines need to handle high pressure of water while resisting fatigue and corrosion.

More mechanisms are also being developed to generate electricity without the turbines. Such as solar cells and internal combustion engines. But their reliability and amount of production is far less than turbines, while they require higher capital and space to build.

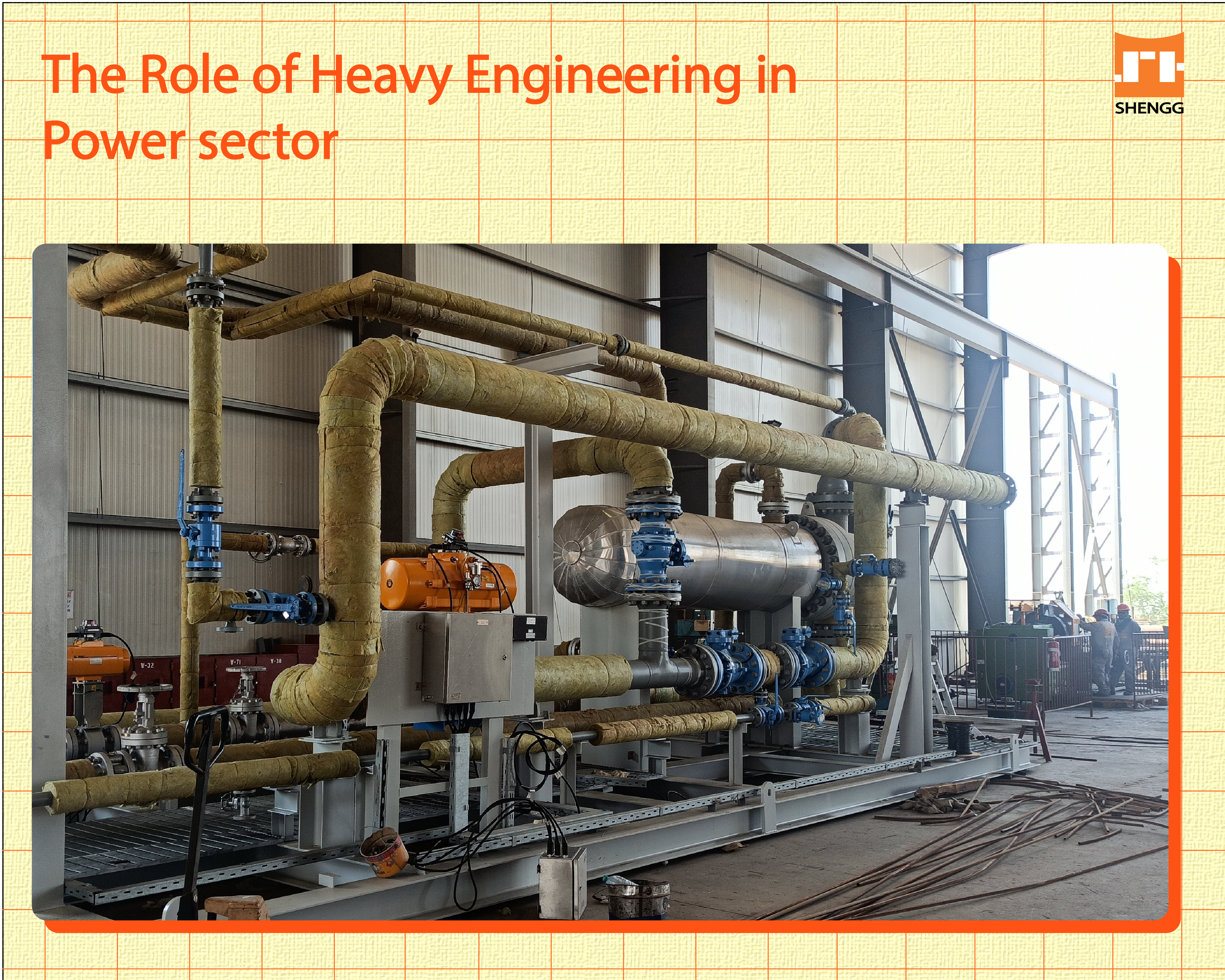

Vessels and heat exchangers

Heat exchangers are pressure vessels used to transfer heat from one medium to another. The mediums can be liquid, gas or both. The mediums are separated by walls to avoid mixing. Heat exchangers provide heating and/or cooling to the system as per the requirement. They maintain the balance of the reactions and flow of the fluids, to have controlled reactions and movements. Titanium, stainless steel, carbon, brass and other alloys are used in making these tanks and tubes.

Heat exchangers are neutral equipment that is used in various other industries apart from the power sector- like technological processes, energy, oil refining, manufacturing, transportation, air conditioning, cryogenic and recovery systems.

Transformers

Transformers are a secondary tool compared to the previous three. They don’t take part in power generation but are integral to transmission, distribution, and utilization processes.

Transformers manipulate the voltage levels- reducing high voltages ranging from 250000V to 500000V coming from power plants to lower levels going in houses ranging from 220V to 100V. This process is not carried out by just one transformer. Transformers come in many shapes, sizes, and materials. Until the electricity reaches our home, it has passed through many types of transformers. The core of the transformer is generally constructed preferably with low carbon steel, though it can also be made with iron and other steels.

Mainly transformers are of two types:

Step-up transformers: used to convert primary voltage to higher level.

Step-down transformers: used to convert primary voltage to lower levels

Beyond these four machines, others are either to support these four or to help in distribution- like batteries, storing facilities, towers, transmission systems, switch gears and control gears.

Technological advancement started with energy. Now that everything is becoming electrical and automated, The structures in the power sector need to be bigger and better. Heavy engineering has the responsibility to keep producing efficient and modern technologies to support these changes. Advancements in heavy engineering are vital to the continued progress of the power sector.