All About: Pressure Vessels

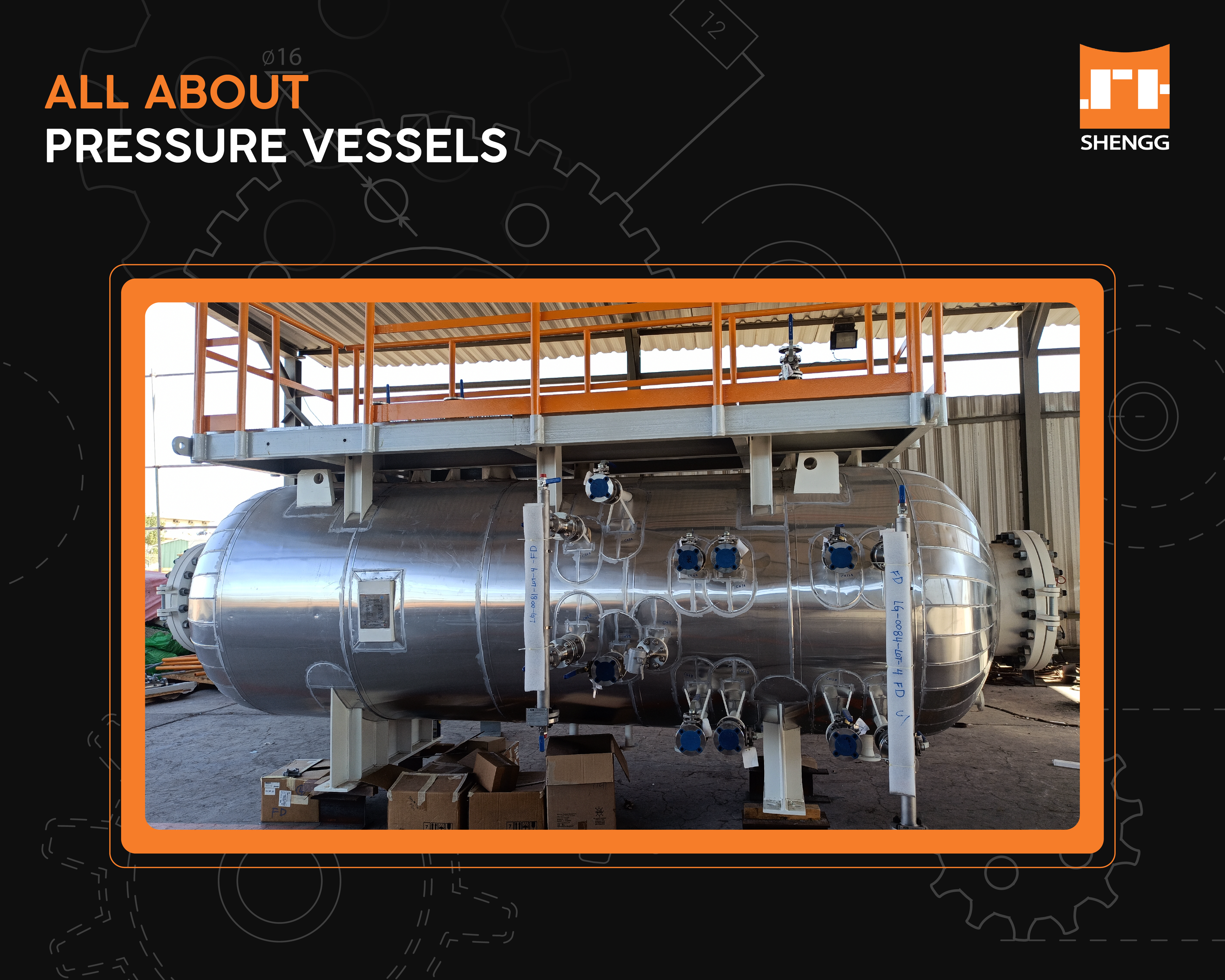

As a heavy equipment manufacturer, we understand the importance of pressure vessels in many industrial processes. In this article, we will provide an in-depth overview of pressure vessels, including their construction process, use, and applications.

Construction Process

Pressure vessels are designed and constructed to withstand high pressure and temperature conditions, and they are typically made from materials such as steel, aluminium, or composite materials. The construction process involves several steps, including design, fabrication, inspection, and testing.

The design phase involves determining the required specifications for the vessel, including the size, shape, and material composition. This is followed by the fabrication process, where the vessel is constructed according to the design specifications. Quality control and inspection are critical during the fabrication process to ensure that the vessel is built to the highest standards of safety and reliability.

Once the vessel is fabricated, it is subjected to rigorous testing to ensure that it can withstand the intended operating conditions. Testing includes hydrostatic testing, which involves filling the vessel with water and pressurising it to the specified pressure level. Any leaks or defects are identified and addressed before the vessel is put into service.

Use and Applications

Pressure vessels are used in a wide range of industrial applications, including in the oil and gas industry, chemical manufacturing, pharmaceuticals, and food and beverage processing. They are used to store and transport a variety of substances, including gases, liquids, and solids, in a pressurised environment.

In the oil and gas industry, pressure vessels are used to store and transport oil and gas products, such as propane and natural gas, under high pressure. They are also used in refineries to store and process crude oil and other petroleum products.

In the chemical manufacturing industry, pressure vessels are used in the production of a wide range of chemical products, such as polymers, plastics, and specialty chemicals. They are also used in the production of pharmaceuticals, where they are used to store and transport sterile fluids and gases.

In the food and beverage industry, pressure vessels are used to store and transport liquids such as beer and soft drinks, as well as gases used in food processing, such as nitrogen and carbon dioxide.

Conclusion

In conclusion, pressure vessels are a critical component of many industrial processes. Their construction process involves several steps, including design, fabrication, inspection, and testing, and they are made from materials that can withstand high pressure and temperature conditions. Pressure vessels are used in a wide range of applications, from the oil and gas industry to chemical manufacturing. Approximately 30% of all projects at SHENGG are Pressure Vessels. As a heavy equipment manufacturer, we understand the importance of pressure vessels in modern industrial processes and are committed to providing our clients with safe, reliable, and high-quality pressure vessel solutions that meet their specific needs.