Quality and Accuracy – The Backbone of Heavy Engineering

Quality and accuracy are the backbone of heavy engineering, and as a process equipment manufacturer, we understand this better than anyone. The process equipment that we produce is essential for many industries, and it plays a critical role in the safe and efficient operation of their processes. That’s why we are dedicated to providing the highest quality equipment, with an unwavering focus on accuracy and precision.

One of the main reasons why quality and accuracy are so important in heavy engineering is that any error or discrepancy in the equipment can result in serious consequences. For example, in the oil and gas industry, an error in the chemical injection skid can result in the release of hazardous chemicals into the environment. In power plants, an incorrect measurement of a turbine or boiler component can cause a catastrophic failure. That’s why we take our responsibility as a manufacturer very seriously and are committed to delivering equipment that is reliable, accurate, and safe.

This starts with the design phase, where our engineers work closely with the customer to understand their specific requirements and develop a detailed design plan that takes into account all of the relevant factors, such as safety, efficiency, and cost.

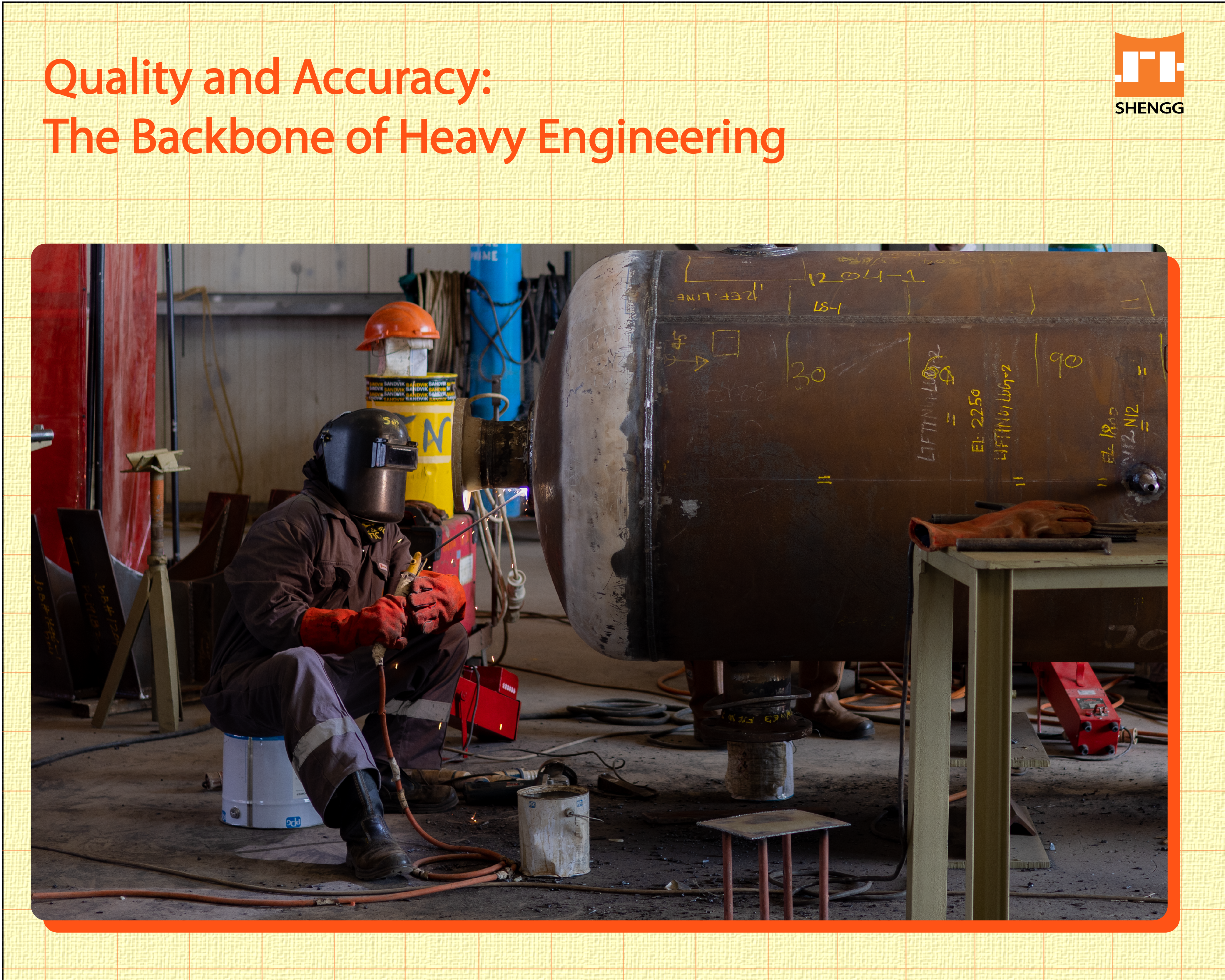

Once the design phase is complete, we move on to the manufacturing process. This involves a range of activities, including fabrication, welding, machining, and assembly. Throughout each of these stages, we employ strict quality control measures to ensure that the equipment is being manufactured to the highest standards. For example, we use precision machinery, such as lathes and milling machines, to shape and finish the components with the greatest accuracy.

In addition to our quality control measures, we also use advanced testing and inspection techniques to ensure the accuracy and reliability of our equipment. This may involve testing the equipment at various stages of the manufacturing process, as well as conducting final inspections before the equipment is shipped to the customer. Our full-fledged quality assurance and control department assures that we meet the highest standards of quality and reliability. We are pre-qualified with a majority of oil field clients, and are recognised by various third-party certification/inspection agencies.

We also invest in our people, as they are the backbone of our business. Our team of engineers and technicians are highly trained and experienced, and they understand the importance of quality and accuracy in heavy engineering. They work tirelessly to ensure that every piece of equipment that leaves our factory is of the highest quality, and they are committed to delivering the best possible customer experience.

Our team of experts from the quality assurance and control department is dedicated to helping clients carry out projects in compliance with quality plans and project requirements. You can depend on us to always uphold the highest standards of quality, from material sourcing to delivery. We create a thorough final project quality document at the conclusion of every project.

SHENGG has an excellent track record working with many classification agencies such as ABS, DNV, TUV, BV, Lloyds, and GL on various projects. We are dedicated to delivering the best, every time.