Role of heavy engineering in oil and gas

Heavy engineering, in general, includes large scale manufacturing products. Such as heavy equipments, ship buildings, machine tools, building construction and infrastructures.

Introduction of heavy engineering has transformed manufacturing. To mass produce, to mass store, and to mass operate indirectly has put food, vehicles, and potable water in every home.

Economic development also took an upside turn after the industrial revolution. With Aerospace, Construction of large buildings, Infrastructures, Oil and Gas, Locomotive,Manufacturing, Shipbuilding, Mining, and Machine Tools Production becoming the main source of jobs in the 1900s; now everyone is enjoying a boom in service sectors.

Oil and Gas industry

The Oil and gas Industry is quite major in heavy engineering itself. As offshore oil and gas excavation is becoming our main source of fuel, none of the rigs can survive with light engineering. Heavy engineering induces a wide range of skills and materials to make any product, for which the plants employ a varied group of people and massive equipment.

Again, to produce, store, and operate in mass; everything increases many folds in terms of size, strength, and quality. Engineering has evolved to meet the fuel needs of people, safety of the environment, and using the full potential of a natural oil reservoir.

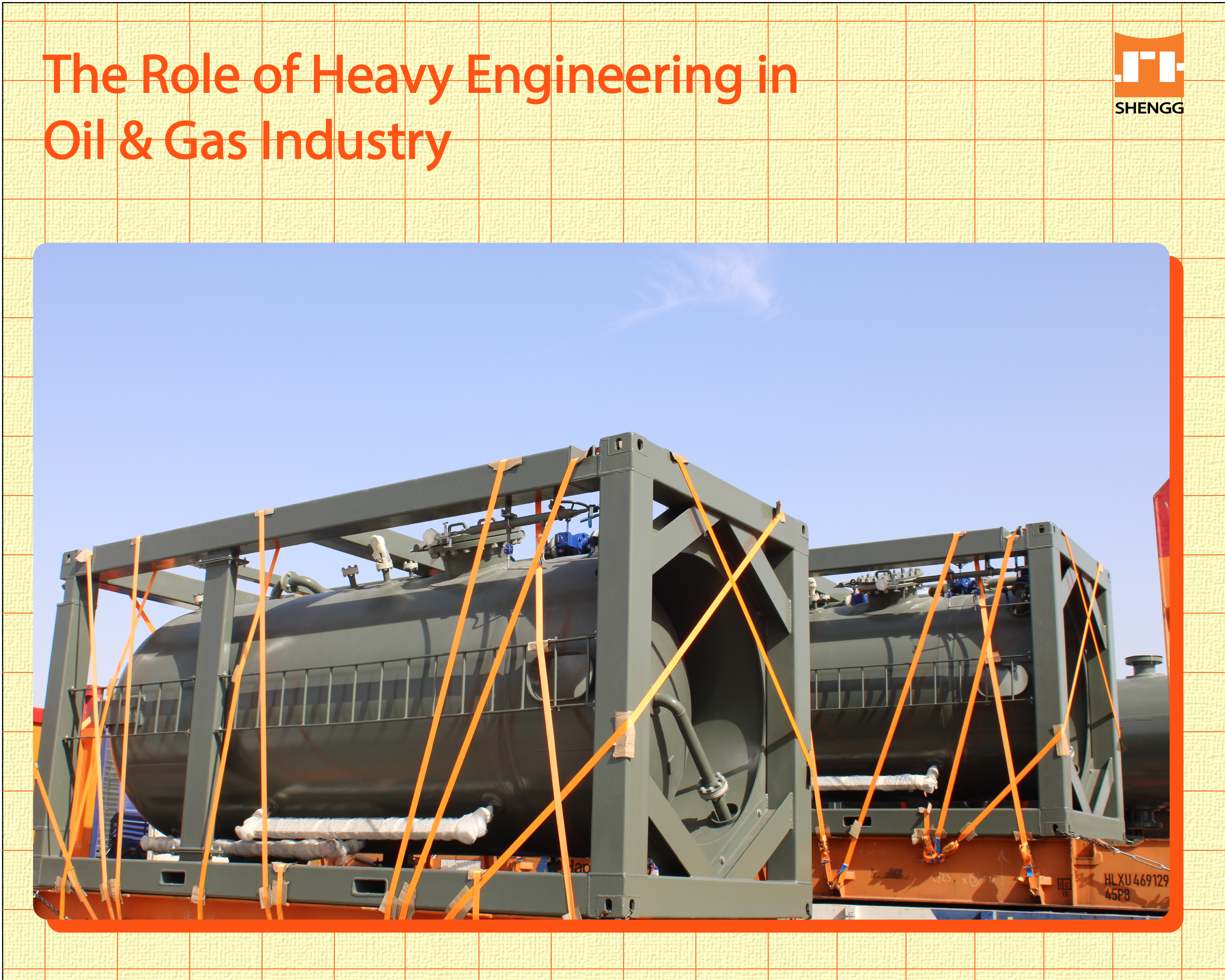

Through the natural reservoir to the petrol pumps; the process requires majorly 5 stages- drilling, extraction, refining, storing and transportation. For each of these stages, mega-equipments are used, especially for storage and collection- such as tanks, skids, columns, reactors, and vessels.

Heavy Equipments

At scale, these equipment share a major percent of heavy engineering in oil and gas.

⦁ Atmospheric storage tanks- These tanks are generally used for fluid that need to be kept under ambient conditions, like- crude oil and other gases.

⦁ Chemical storage and transportation tanks- These tanks are generally used for storing, mixing and transporting chemicals. Materials of structure are based on the target chemical, as they might react with the metal of the tank.

⦁ Distillation columns- These tube tanks provide space for condensation and evaporation to the fluids and gases before they move to the condenser.

⦁ Glycol regeneration skid- This skid system is used for dehydrating the natural gases.

⦁ Pressure/process/filtration vessels- These are smaller tanks used for similar processes; like reverse osmosis, ambient conditioning, filtration etc.

⦁ Gas dehydration skids- These again are the skid system, used for dehydrating the natural gases.

⦁ Pressure piping- pressure piping system is used for many industrial processes, in heating and cooling systems, fire protection installations, gas distribution, and for water supply and distribution.

Heavy engineering is the main reason for such innovations and raising the economy. Heavy engineering is a craft, it has the ability to be intricate in designing rather particular equipment for the nature of the fluids. It’s like, heavy engineering understands the psychology of process and fluids. Crafting the pathways and stations in all the steps of the system.

The plants, rigs, factories, and all manufacturing infrastructure has grown in size. For this reason mass manufacturing has become easy. It helped in recruiting more employees as well, which further pushed the rise in economic development around the world.

We at SHENGG, aims to be a leading global process equipment manufacturer and modular process systems provider for oil, gas, petrochemicals, food & dairy, marine, desalination and energy sectors.